|

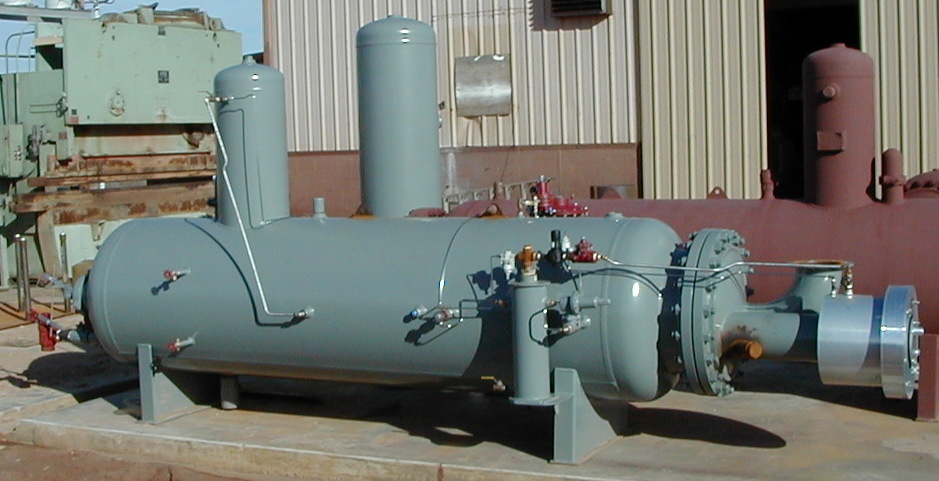

Vesco, Inc. is producing a low pressure direct fired production unit.

The unit can be used on wells that require both a separator and a heater treater. This 36" X 10' horizontal production unit allows you operate one unit instead of two. The unit operates at a maximum working pressure of 250 psi, while the burner is rated at 350,000 BTU/HR. The actual amount of total fluid which can be effectively treated depends ultimately on the oil/water ratio, oil viscosity, treating temperature, oil and water densities, chemical reactions and periodic peak flow rates. The actual gas capacity depends on the gas gravity, gas temperature, operating pressure, and the magnitude of the pressure cut necessary to produce the well. Oil and Water Box The use of an oil dam and adjustable water weir allows effective control of both oil and water levels and eliminates problems associated with interface control in small-diameter horizontal vessels. The oil flows over the oil dam into the oil box and the water flows through the adjustable weir nipple. The weir is adjustable to allow for variations in oil/water specific gravity or oil retention time. Gas Dome and Dryer The gas leaves the production unit through a mist extractor installed in the gas dome. A back-pressure valve or the sales line pressure controls the vessel operating pressure. A gas dryer permits instrument and fuel gas to be taken out of the main stream at the highest possible point, hence minimizing liquid carryover to the fuel and instrument systems Vesco, Inc. became a code fabrication facility in 2002, obtaining 2 code stamps. The ASME "U" code stamp certifies that our new code fabrication is built to ASME code specifications and The National Board "R" code stamp allows us to make repairs to code vessels under The National Board standards. Vesco, Inc. usually has a selection of code separators fabricated, tested, inspected and painted in stock. If you are looking for an A.S.M.E. code pressure vessel, be sure to let Vesco, Inc. meet your needs. Contact Vesco, Inc for all of your A.S.M.E. code fabrication needs. If you want to check our stock, receive a quote or just ask a few questions, please contact us at (580) 256-2569 or e-mail us!

|

Vesco Inc

211 N 48th St

Woodward Ok 73801

Phone 580-256-2569 Fax 580-256-4262

Site powered by Weebly. Managed by iHost Networks